About

Arslan Makina has been serving as a reliable supplier in the aluminium industry for over 50 years with a value-driven production and with a solution-focused approach.

We produce value-added aluminium components with our expertise in various manufacturing processes such as Aluminium Die Casting, Tooling Design and Manufacturing, Machining, Aluminium Forging, Heat Treatment (T4-T5-T6) and Electrostatic Powder Painting. Prioritising customer satisfaction, we deliver high-quality aluminium products to ur customers on time through the use of cutting-edge technologies and precise planning.

Value-driven production

We provide our customers with high-quality, effective and efficient products and services that meet their expectations. We focus on efficiency on every stage from production to delivery and the assembly line of our customers, producing value-added components.

Solution-focused approach

We demontrate a solution-focused approach to best meet the needs of our customers. We promptly respond to customer enquiries, provide solutions to their issues, and offer technical support whenever needed. We prioritise efficient production and effective communication for each customer by closely monitoring our delivery processes as well.

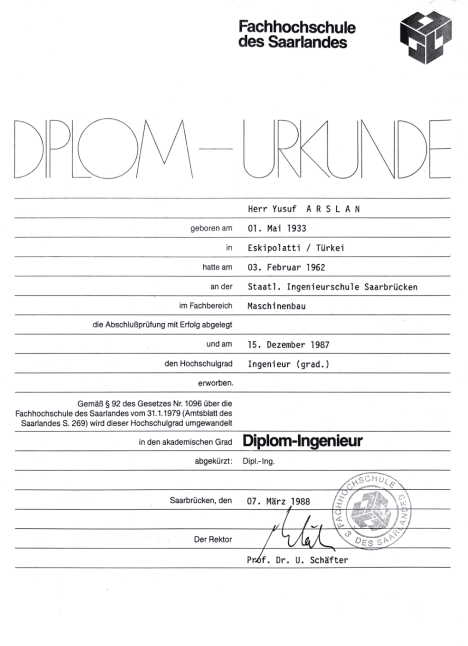

History

Arslan Makina has been serving as a reliable supplier in the aluminium industry for over 50 years with a value-driven production and with a solution-focused approach.

Our company, founded with great dedication by Yusuf Arslan, continues to operate in its 13.000 m2’lik factory under the management by the second generation of the founding family. Combining our vast experience with investments of latest technology, we offer sustainable and efficient cooperation. With the strength and synergy created by teamwork, we continue to grow on a global scale.

Our Values

We continously improve our production processes by investing in technology. We aim to ensure precision in manufacturing of all our products for every customer and to achieve top-level product quality.

We prioritise establishing open and honest communication with our customers and value transparency throughout the entire business processes. We provide clear and timely information to our customer regarding the quality of our products, delivery dates and costs, ensuring flawless deliveries on scheduled dates. Honest communication and mutual trust are indispensable for us.

With our engineering, design and manufacturing capabilities, we offer customised solutions and flexibility for our customers in our business processes.

We are working for people and we cherish nature. We aim to conduct an eco-friendly production process to protect the ecosystem with every stakeholder. We engage in initiatives such as waste reduction, energy conservation, water efficiency, waste management and a sustainable supply chain.

Visit our Sustainability and Environment page for more information on our initiatives.